| 分類 | 種類 |

英國箸名品牌 Grade 10.9 Tension Control Bolts

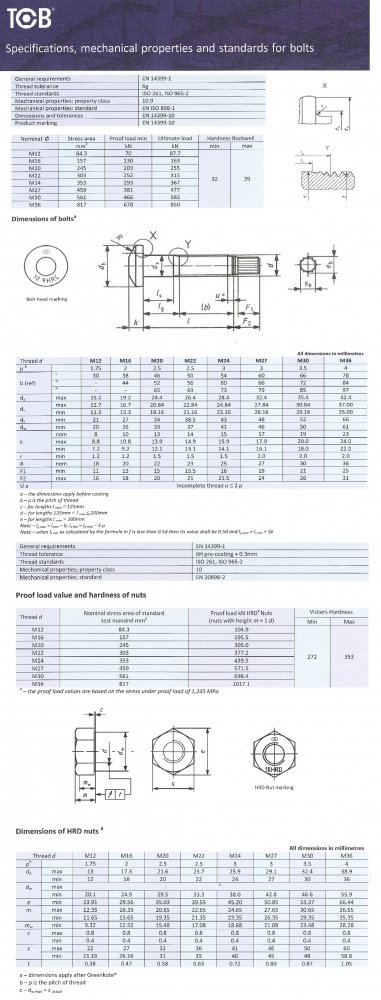

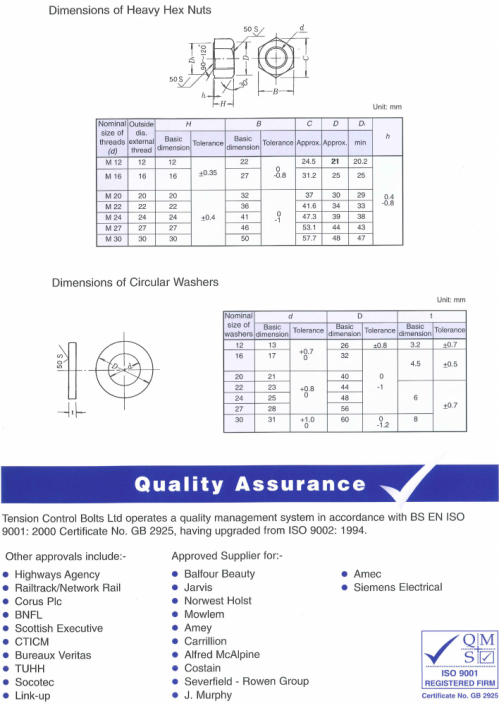

| 規格 | Tension Control Bolts Ltd operates a quality management system in accordance with BS EN ISO 9001:2008 Certificate No. FS 86045 |

|---|

Tension Control Bolts

Tension Control Bolts Ltd operates a quality management system in accordance with EN ISO 9001:2000 certificates no. GB2925,

having upgrade from ISO 9002:1994.

HIGH STRENGTH TENSION CONTROL BOLTS (TCB)

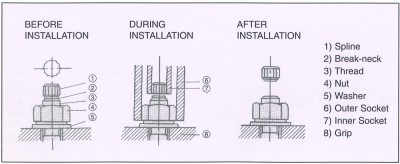

It is the lowest cost method for properly installed High Strength Friction Grip Bolts. They are quick, safe and easy to install using non impacting electric shear wrenches with varying shapes and sizes available. One man installation and no torque wrenches are required. Guaranteed consistent tension together with visual inspection removes the like hood of operator error and ensures engineers that connections are tightened in accordance with specifications. It also reduces operator fatigue, tool maintenance and on-site noise levels.

Greenkote® Qualified for Eureka Status.

TCB have built a new innovative diffusion coating plant incorporating the very latest technology for the coating of their bolts, nuts and washers. The process is a Thermo-Chemical Surface Modification (TCSM) and can be used for various metals, alloys, sintered ferrous-based materials, grey iron & cast iron.

TCSM production process (Greenkote®) is totally environment friendly. Unlike conventional coatings, Greenkote® does not produce any solid, liquid or gaseous toxic wastes. The process is also free of chrome, cadmium, acids, cyanides and chlorides.

Type of coating: PM-1.

Coating composition: Zn-Al polymetallic composition.

Main coatings' properties:

Diffusion sacrificial corrosion resistance coating

Thickness can be adjusted to suit different applications e.g. from 20 to 100µm

Salt spray resistance - up to 1200 hours

Long-term corrosion protection up to 350°C (752°F)

No hydrogen embrittlement

Thickness uniformity ±10% maximum

Excellent preparation for painting, duplex coatings, adhesives and rubber mouldings. eg. from 20 to 100µm (TCB standard 25µm)

Comparison of Coatings in ASTM B117 Salt Spray Test

The criterion for failure was more than 5% of the sample area covered by red corrosion.

The Greenkote® sample was acceptable after 800 hours of testing.

Job Reference:

City of Dream 新濠天地 (2008)

Windor Arch Macao 名門世家 (2013)

Parisian Macao 澳門巴黎人 (2016)

LISBOA Palace 上葡京娛樂場 (2016)